Operational Excellence in Steel Plant

- ansoim

- Aug 25, 2024

- 8 min read

In the steel manufacturing industry, where profits are minimal, and the need to optimise production is high, Operational Excellence in Steel Plant is not just a plan—it's a necessity.

Steel plants, with their intricate machinery, complex supply chains, and strict quality requirements, face unique challenges that require experience, innovation, and strategic thinking. For Managing Directors and senior leaders who have spent years navigating this industry, achieving operational excellence means driving continuous improvement that sustains profitability and sets the stage for long-term success.

This article delves into the key areas where operational excellence can be achieved within a steel plant.

From process optimisation and quality management to digital transformation and workforce development, each section is tailored for seasoned professionals, offering practical insights, advanced strategies, and advanced concepts that can help you meet and exceed industry standards.

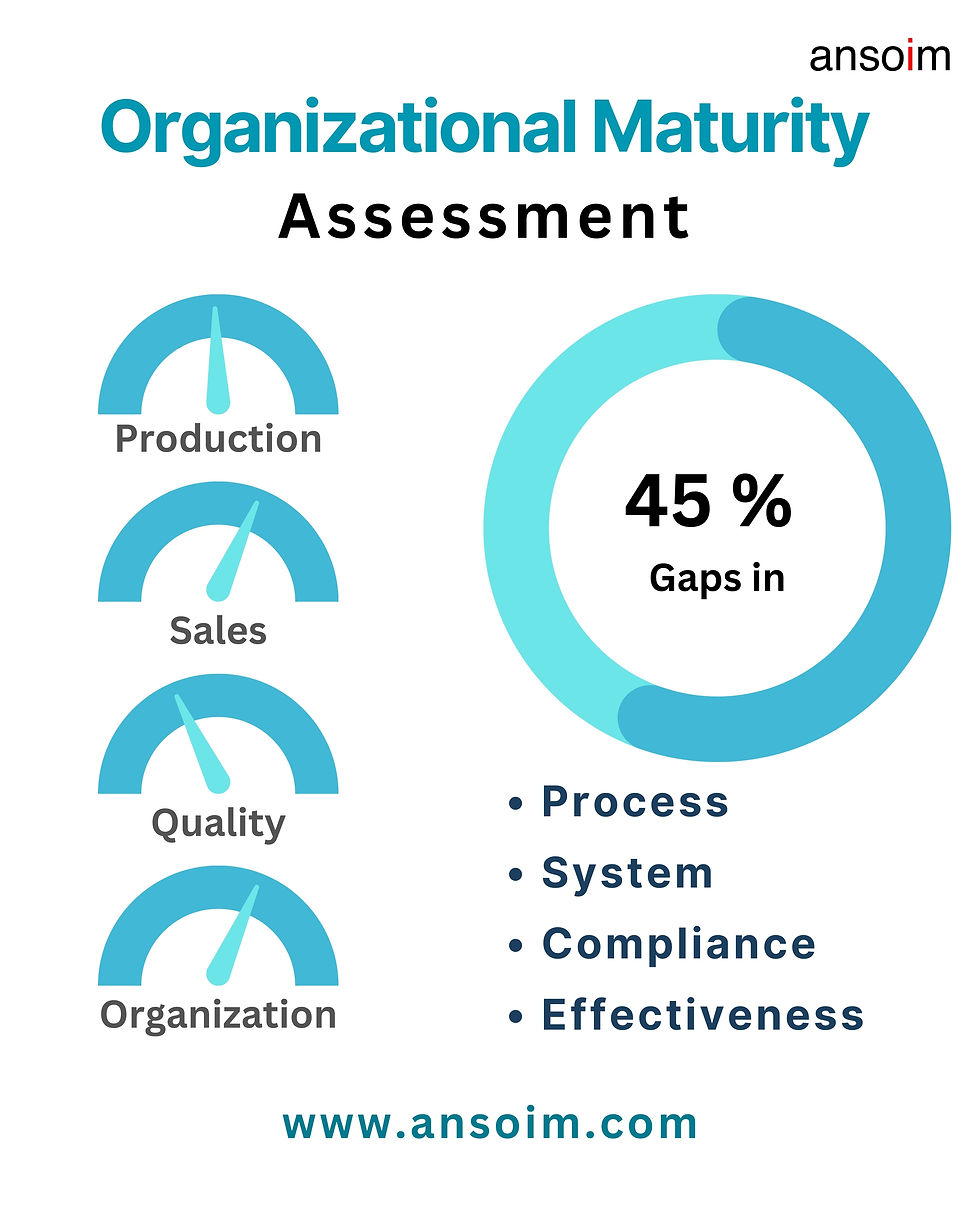

Scope of Operational Excellence in Steel Organisation

Whether you aim to enhance your critical equipment's reliability, streamline your supply chain, or leverage digital tools to boost efficiency, this strategic playbook will guide you through the complexities of operational excellence in steel plants. Let’s explore how you can turn challenges into opportunities and lead your plant toward a future of sustained excellence.

Process Optimisation: The Bedrock of Operational Excellence in Steel Plant

In the complex environment of steel manufacturing, where every process is interconnected, process optimisation is the lifeblood of efficiency. The challenge lies in fine-tuning each stage—from ironmaking to rolling—while maintaining the delicate balance between speed, quality, and cost.

Ironmaking and Steelmaking

Maximising furnace efficiency is crucial for a profitable steel plant. People in charge of blast furnaces need to carefully balance reducing coke consumption with improving fuel efficiency. By optimising the composition of the materials and improving thermal efficiency, you can increase output and cut costs. Electric Arc Furnace (EAF) operators focus on reducing energy consumption and minimising electrode wear to improve performance. Efficiency is key in both cases, leading to significant cost savings and better overall performance.

Dynamic Process Modelling

Steel plants can simulate various operational scenarios to continuously optimise furnace efficiency by integrating dynamic process models with real-time data analytics. This involves using machine learning algorithms that adapt to changing input conditions, predicting the best operational settings to minimise coke usage and maximise yield without sacrificing quality.

Continuous Casting

Professionals know that casting speed and cooling rate are not just parameters—they are critical levers. Subtle adjustments here can mean the difference between a slab requiring extensive rework and one ready for the rolling mill.

Virtual Sensor Technology

Implementing virtual sensors—software-based tools that infer critical process parameters from existing measurements—can provide more precise control over casting operations. These sensors use advanced algorithms to estimate parameters like mould heat flux or liquid steel level with greater accuracy than traditional sensors, enabling finer adjustments and reducing defects.

Rolling Operations

The key to excellence in rolling lies in precise control over temperature profiles and deformation rates. Based on advanced sensing technologies, real-time process adjustments can significantly reduce defects and improve yield.

Inline Rolling Process Optimization Using AI

By deploying AI-driven process optimisation tools, rolling operations can benefit from systems that learn continuously and adjust rolling parameters in real time. These systems analyse vast amounts of data from sensors embedded in the rolling mills, allowing them to predict and prevent potential issues, thereby reducing defects and enhancing throughput.

Quality Management: Beyond Compliance

In the steel industry, maintaining quality is a given, but what sets leaders apart is their ability to go beyond mere compliance and set new standards for excellence.

Advanced Quality Control

Seasoned professionals leverage tools like XRF and ultrasonic testing for quality assurance and refining processes. By integrating these tools into the feedback loop, you can identify the root causes of deviations and adjust upstream processes accordingly.

Real-Time Adaptive Quality Control Systems

Real-time adaptive quality control systems enable steel plants to adjust production parameters based on real-time quality data automatically. These systems use advanced machine learning algorithms to identify patterns and predict quality deviations before they occur, allowing for preemptive adjustments that maintain product consistency and reduce waste.

Culture of Quality

Building a culture where every worker, from the furnace operator to the quality inspector, takes ownership of product quality is essential. This isn’t about one-off training sessions—it’s about instilling a mindset where quality is everyone’s responsibility.

Quality Governance Frameworks

Implementing a robust quality governance framework ensures that quality management is integrated into every aspect of the operation. This framework includes regular quality audits, cross-functional quality councils, and a continuous feedback system that encourages innovation in quality improvement across the organisation.

Maintenance and Reliability: The Pulse of Operational Excellence in Steel Plant

Steel plants are capital-intensive environments where equipment uptime directly correlates with profitability. For experienced leaders, maintenance and reliability are not just cost centres but strategic functions.

Predictive Maintenance (PdM)

All professionals are familiar with the benefits of PdM, but the real challenge lies in its implementation. Remember to use the data from your plant's assets such as vibration analysis, thermography, and lubricant testing to predict failures before they occur instead of just reacting to them.

Prescriptive Maintenance

Beyond predictive maintenance, prescriptive maintenance predicts when a failure will occur and prescribes the best course of action to prevent it. This involves advanced analytics recommending specific maintenance tasks, resources, and timings, maximising equipment uptime and reducing unnecessary maintenance activities.

Reliability-Centered Maintenance (RCM)

Integrating RCM practices helps prioritise maintenance activities based on equipment criticality. This approach ensures that resources focus on the most crucial assets, maximising operational availability.

Reliability Engineering Using Digital Twins

Reliability engineers use digital twins to create virtual copies of physical assets. These replicas help simulate different operating conditions and maintenance scenarios. This allows them to identify potential failure points and optimise maintenance schedules without disrupting actual operations, improving equipment reliability and reducing maintenance costs.

Supply Chain Optimisation: The Hidden Lever

Supply chain optimisation can mean the difference between meeting your margins and falling short. For steel professionals, it's important to focus on being flexible and strong. This means making sure that the supply chain can handle both expected and unexpected problems.

Integrated Supply Chain Management

Use real-time data integration across your supply chain to synchronise procurement with production schedules. This minimises inventory holding costs while ensuring material availability.

Supply Chain Control Towers

Implementing a supply chain control tower provides end-to-end visibility across the supply chain. These control towers leverage AI and big data analytics to monitor, predict, and manage real-time supply chain disruptions, enabling faster decision-making and more agile responses to market changes.

Strategic Supplier Partnerships

Move beyond transactional relationships with suppliers. By fostering partnerships, you can secure priority access to raw materials and negotiate better terms that reflect your long-term value to their business.

Collaborative Planning, Forecasting, and Replenishment

Adopting CPFR with key suppliers ensures both parties collaborate on demand forecasting and inventory planning. This advanced approach aligns production and procurement activities more closely, reducing the risk of supply shortages and enhancing the efficiency of the entire supply chain.

Workforce Development: The Human Edge of Operational Excellence in Steel Plant

People are your most valuable asset, even in the steel industry, dominated by heavy machinery and complex processes. Experienced professionals understand that workforce development is non-negotiable.

Advanced Training Programs

Go beyond the basics with training tailored to your plant’s specific needs and processes whether advanced metallurgy for your quality teams or predictive analytics for your maintenance crew, targeted skill development pays off in performance.

Adaptive Learning Platforms

Implementing adaptive learning platforms allows personalised training experiences that evolve based on individual progress and performance. These platforms use AI to tailor training content to each employee's needs, ensuring they acquire the necessary skills more effectively and efficiently.

Engagement and Empowerment

Experienced leaders know that an engaged workforce is a productive one. Empower your employees by involving them in decision-making processes and recognising their contributions. This not only improves morale but drives continuous improvement from the ground up Operational Excellence in Steel Plant.

Employee Innovation Programs

Establishing structured employee innovation programs encourages frontline workers to contribute ideas for process improvements. By creating a formal mechanism for capturing, evaluating, and implementing these ideas, you tap into a wealth of operational insights that can lead to significant performance gains.

Digital Transformation: Embracing the Future

Digital transformation in steel manufacturing isn’t just a trend—it’s a necessity for staying competitive. However, for seasoned professionals, the challenge lies in integrating these technologies into existing processes without disrupting operations.

IoT and Real-Time Monitoring

IoT devices have evolved beyond mere sensors. They are now integral tools for process control and optimisation. Use IoT to monitor critical parameters in real-time, enabling immediate corrective actions that prevent minor issues from becoming significant disruptions.

Edge Computing in IoT Systems

By implementing edge computing, steel plants can process IoT data locally, closer to where it is generated, rather than relying on centralised data centres. This reduces latency, allows for faster decision-making, and ensures more reliable operations, particularly in intermittent network connectivity.

AI and Machine Learning

For steel professionals, AI is more than a buzzword. It’s a tool that, when properly harnessed, can optimise everything from energy consumption to predictive maintenance schedules. The key to success lies in the data; ensuring that your AI systems are provided with high-quality and relevant data to generate actionable insights.

Explainable AI (XAI)

Implementing explainable AI ensures that the AI-driven decisions in your plant are transparent and understandable. XAI provides clear reasoning behind AI predictions and recommendations, enabling human operators to trust and effectively collaborate with AI systems. This leads to better integration of AI into complex decision-making processes.

Cost Reduction: Strategic, Not Sacrificial

Reducing costs at a steel plant is about making smart decisions to improve efficiency without sacrificing quality or safety. It's not about cutting corners.

Lean Manufacturing

Apply Lean principles to eliminate waste in all forms—be it excessive inventory, unnecessary material movement, or overproduction. The goal is to streamline operations so that every step adds value.

Lean Digitalization

Lean methodologies can be improved by combining digital tools with Lean principles, such as digital Kanban systems, automated value stream mapping, and real-time analytics. This approach, known as Lean Digitalization, allows for more precise tracking and elimination of waste, driving further efficiencies in steel production.

Energy Efficiency

Energy is one of the largest operating costs for steel production professionals. To reduce consumption without impacting output, focus on optimising furnace operations and implementing energy recovery systems.

Energy Management Systems (EMS) with AI Integration

Deploying an AI-integrated Energy Management System allows for continuous monitoring and optimisation of energy usage across the plant. These systems can predict peak energy demands, optimise load distribution, and suggest energy-saving measures in real time, reducing overall energy costs while maintaining production efficiency.

Production Planning and Control: Precision in Execution

The steel industry's ability to execute a precise production plan separates top performers from the rest. For experienced professionals, this means meeting targets and exceeding them through strategic planning and real-time control.

Advanced Planning Systems

Utilise Manufacturing Execution Systems (MES) that integrate with your enterprise resource planning (ERP) systems. This allows for seamless coordination between production schedules and material availability, reducing downtime and ensuring on-time delivery.

Advanced Planning and Scheduling (APS) Systems

Implementing APS systems provides a higher level of precision in production planning. These systems use complex algorithms to optimise production schedules based on multiple variables, including machine availability, material supply, and customer demand, ensuring maximum efficiency and responsiveness.

Dynamic Scheduling

Static schedules are ineffective in a high-variability environment like a steel plant. Instead, implement dynamic scheduling tools that can adapt to real-time changes in production capacity, order priorities, or unexpected disruptions.

Resilient Operations Planning

Creating flexible production schedules is key to developing resilient operations planning. These schedules should adapt quickly to disruptions like supply chain issues, equipment failures, or changes in demand. This approach uses scenario analysis and contingency planning to meet production goals under varying conditions.

Conclusion: Operational Excellence in Steel Plant as a Strategic Imperative

For those who have spent years in the steel industry, achieving Operational Excellence in Steel Plant is about more than just incremental improvements—it’s about transforming how you operate from the ground up.

Focusing on process improvement, quality control, equipment maintenance, efficient supply chain, employee training, digital upgrade, cost control, and production planning will help your steel plant succeed in the competitive global market.

Operational Excellence in Steel Plant is not a destination but a journey. For experienced leaders, it’s a continuous pursuit that demands strategic foresight and relentless execution. Embrace this mindset, and you will drive your plant’s performance to new heights and secure its future in the evolving landscape of steel manufacturing.

_edited_edited_edite.png)