The integration of Artificial Intelligence (AI) into manufacturing is more than a technological evolution; it’s a revolution poised to redefine the industry’s landscape.

For CXOs, AI's promise extends beyond operational efficiency—it’s about strategic transformation.

Let's delve into how AI is reshaping manufacturing and why it should be at the top of your strategic agenda.

Predictive Maintenance | Quality Assurance | Supply Chain | Human Capability | Implementation Challenges | Conclusion

Predictive Maintenance: AI in Manufacturing

Conventional maintenance methodologies frequently result in unforeseen downtimes and inefficiencies. However, AI-powered predictive maintenance leverages machine learning algorithms and IoT sensor data to predict equipment failures before they happen. This proactive strategy not only minimizes downtime but also enhances maintenance scheduling and extends equipment lifespan.

Uses machine learning algorithms to analyze historical and real-time data.

Utilizes IoT sensors to monitor equipment performance continuously.

Identifies patterns and anomalies indicative of potential failures.

Forecasts equipment failures, enabling timely intervention.

Plan for scheduled maintenance during non-peak hours.

Reduces the breakdown, minimizing production disruptions.

Prevents minor issues from escalating into major problems.

Ensures machinery operates within optimal parameters.

Enhances the overall lifespan of assets.

This isn’t just about fixing things before they break. It’s about creating a culture of proactive problem-solving and continuous improvement. Imagine a world where maintenance isn’t a headache but a well-oiled part of your operation. That’s the AI advantage.

Quality Assurance: Beyond Human Capabilities

Quality control is critical in manufacturing, but traditional methods have limitations. Advanced computer vision systems and machine learning models of AI offer precision and speed that surpass human capabilities.

AI-driven quality assurance systems can detect minor defects and variations in real-time, ensuring that only high-quality products reach the market.

Employs computer vision to capture detailed images of products and process.

Uses machine learning to analyze these images for defects.

Identifies inconsistencies that might be missed by the human eye.

Continuously monitors the production line for quality issues.

Provides instant feedback, allowing for immediate corrective actions.

Reduces the incidence of defective products reaching the market.

Maintains stringent quality standards across all production batches.

Minimizes human error in quality assessments.

Enhances the overall reliability of the manufacturing process.

This shift to AI in quality assurance fosters a culture of excellence and accountability. Your team isn’t just catching mistakes—they are ensuring perfection from the start. That’s transformative.

Supply Chain Optimization: The Strategic Edge

AI plays a critical role in manufacturing by serving as the arteries, while the supply chain acts as the lifeblood that ensures smooth operations.

AI algorithms are employed to analyze extensive datasets to predict demand, optimize inventory, and enhance logistics processes. This leads to a flexible and robust supply chain that can swiftly adjust to market changes.

Analyzes historical sales data and market trends.

Predicts future demand with greater accuracy.

Helps in planning production schedules more effectively.

Monitors stock levels in real time.

Determines optimal inventory levels to prevent overstocking or stockouts.

Reduces carrying costs and frees up capital.

Optimizes routing and scheduling for transportation.

Ensures timely delivery of raw materials and finished products.

Enhances overall supply chain efficiency.

Imagine a supply chain that anticipates needs before they arise. That’s the power of AI—turning your supply chain into a dynamic, responsive entity that adapts in real-time. It’s about creating a culture of agility and responsiveness.

Human-Machine Collaboration: Redefining the Workforce

AI’s true potential lies in augmenting human capabilities. By taking over repetitive, hazardous, and data-intensive tasks, AI allows human workers to focus on strategic, creative, and decision-making roles. This shift not only boosts productivity but also enhances job satisfaction and safety.

Handles repetitive tasks.

Performs hazardous tasks, reducing workplace injuries.

Manages data-intensive tasks with high accuracy and speed.

Frees up human employees to engage in strategic planning and problem-solving.

Encourages creativity and innovation in the workforce.

Improves job satisfaction by reducing monotonous work.

Creates a safer work environment by mitigating exposure to dangerous tasks.

Enhances overall productivity by leveraging AI’s capabilities.

Promotes a collaborative environment where humans and AI work in synergy.

This isn’t just automation—it’s about cultivating a culture where humans and machines complement each other, enhancing overall organizational capabilities. It’s about making work smarter, safer, and more satisfying.

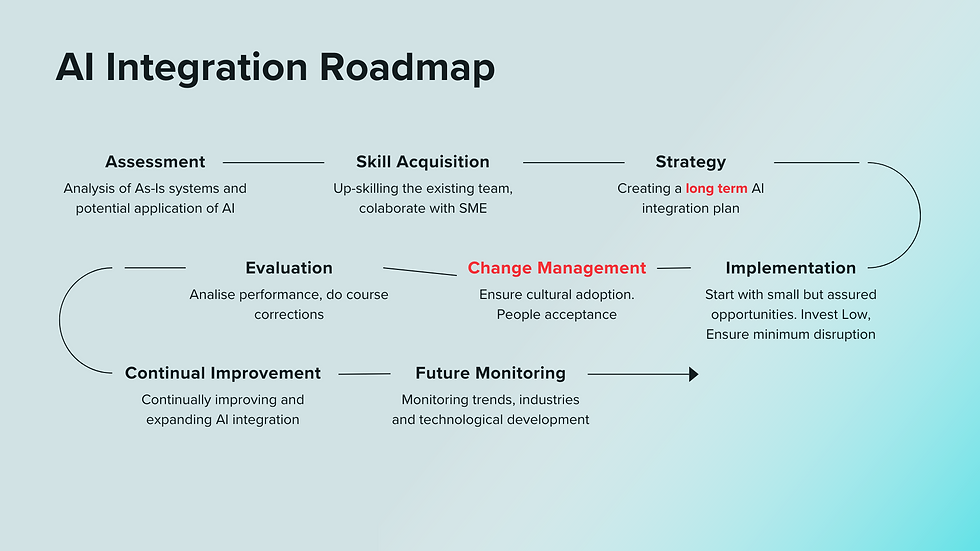

Overcoming Implementation Challenges: A Strategic Approach

The path to integrating AI presents various challenges, such as technology investment, data security, and legacy system integration. However, the strategic benefits far outweigh these obstacles.

Allocate resources for advanced AI systems and infrastructure.

Prioritize scalable and flexible solutions that can grow with the business.

Implement robust cybersecurity measures to protect sensitive data.

Establish protocols for data governance and compliance.

Develop strategies for seamless integration of AI with existing systems.

Ensure interoperability and data consistency across platforms.

Combine AI experts with domain specialists to drive innovation.

Foster collaboration across departments to facilitate smooth implementation.

Promote an organizational mindset that embraces change and experimentation.

Provide training and development opportunities for employees.

Overcoming these challenges isn’t just about technical solutions—it’s about fostering a culture of innovation and resilience. It’s about creating an environment where change is embraced, not feared.

Conclusion: The AI-Driven Future

AI in manufacturing is not just an operational upgrade; it’s a strategic imperative. It offers unparalleled opportunities to enhance efficiency, quality, and agility.

For CXOs, the challenge is to harness AI’s potential to drive long-term growth and sustainability.

Elevates manufacturing efficiency and product quality.

Enhances agility in responding to market demands.

Positions the organization at the forefront of industry innovation.

Leads to sustained competitive advantage and market leadership.

Embrace AI, and transform challenges into opportunities, inefficiencies into optimizations, and potential into reality. The future is now, and it’s intelligent.